HRL Laboratories Unveils SPARES: A Revolutionary Approach to Structural Reliability Assessment

HRL Laboratories Unveils SPARES: A Revolutionary Approach to Structural Reliability Assessment

HRL Laboratories introduces SPARES (Surrogate‐accelerated, Physics‐guided Assessment for the Reliability of Structures), a DARPA-funded project to deliver faster, smarter and more efficient structural reliability analysis for metal parts by leveraging the layer-by-layer nature of additive manufacturing.

MALIBU, Calif.--(BUSINESS WIRE)--HRL Laboratories is introducing SPARES (Surrogate‐accelerated, Physics‐guided Assessment for the Reliability of Structures), a breakthrough project that leverages the layer-by-layer nature of additive manufacturing to deliver faster, smarter and more efficient structural reliability analysis for metal parts, providing fatigue performance data without destructive testing.

“SPARES is about efficiency without compromise,” said Eric Clough, Principal Investigator at HRL Laboratories.

Share

About SPARES

SPARES combines physics-based modeling with machine learning-driven surrogate models to dramatically reduce the time and computational effort required to evaluate structural integrity, without sacrificing accuracy.

- SPARES is a DARPA-funded effort under the SURGE (Structures Uniquely Resolved to Guarantee Endurance) program, recognizing HRL’s leadership in advancing structural reliability assessment.

- SPARES is developed in collaboration with: Boeing, Purdue University and the University of Utah.

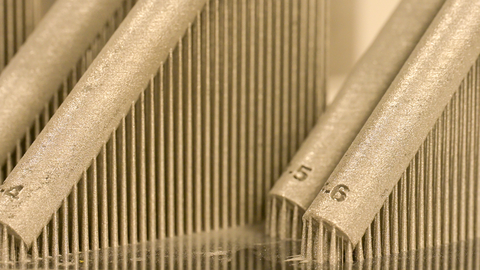

- SPARES leverages Fringe Inspection™, a real-time, layer-by-layer topology inspection product from Phase3D, that provides objective data of the additive manufacturing process.

What you need to know

Reliability assessments are critical for industries like aerospace, automotive and civil engineering, where materials and structures must withstand extreme conditions over time. Traditional methods rely on complex simulations or large-scale physical testing, both of which can be slow and expensive.

SPARES tackles this challenge by:

- Collecting sensor data and in-situ monitoring during the additive manufacturing process.

- Using surrogate models, which are streamlined, AI-assisted versions of full-scale simulations, to rapidly predict how structures will perform under stress.

- These models are informed by real physics to ensure that results remain reliable even as computational effort is reduced.

“SPARES is about efficiency without compromise,” said Eric Clough, Principal Investigator at HRL Laboratories. “By embedding advanced physics principles into AI-driven models, we’re able to speed up the reliability assessment process while maintaining the accuracy engineers need to make critical decisions.”

Dig deeper

This hybrid approach makes it possible to assess failure risks, predict material performance and optimize designs in a fraction of the time required by conventional methods. Whether evaluating aircraft components, vehicle frames or infrastructure items, SPARES provides engineers with fast, physics and data-driven insights to enhance safety and durability.

HRL Laboratories, alongside its esteemed partners, is committed to developing innovative solutions that address real-world engineering challenges. SPARES is a testament to that mission, pushing the boundaries of structural reliability research and paving the way for smarter, more resilient designs.

HRL Laboratories, LLC, California (www.hrl.com) pioneers the next frontiers of physical and information science. Delivering transformative technologies in automotive, aerospace and defense, HRL advances the critical missions of its customers. As a private company owned jointly by Boeing and GM, HRL is a source of innovations that advance the state of the art in profound and far-reaching ways.

Contacts

media@hrl.com

310-317-5000